One of the major industries that utilize stainless steel hinges includes the marine industry. Stainless steel hinges are particularly useful in this industry because boats endure harsh environmental conditions as well as dwelling in highly corrosive areas; stainless steel hinges are used to hold back corrosion and rust for as long as possible. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Slip hinges, continuous hinges, butt hinges, flag hinges and any custom hinge need – Delson Hinge has over 50 years of experience to bring you a better hinge making process. Not only the highest quality standard and custom hinges, but also exceptional service, prices and turnaround. With custom hinge design being our forte, Delson can truly say that we offer a hinge for every need!

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Stainless Steel Hinge Manufacturers

Additional industries that benefit from stainless steel hinges include construction, architectural, automotive, furniture, commercial, industrial, residential and electronics. A long list of stainless steel hinge applications includes exterior and interior doors, tool boxes, electronic enclosures, barn doors, commercial bus doors, horse trailers, winery doors, fire truck compartments, storm doors and ATM machines. Stainless steel hinges may offer mill, bright annealed or polished finishes.

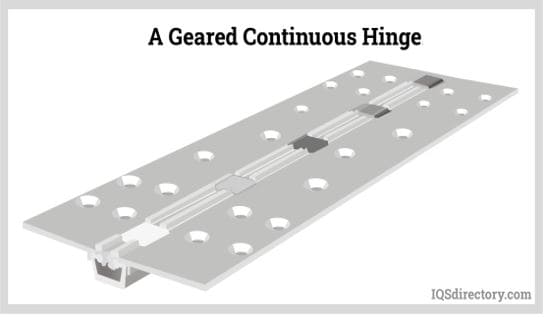

All of the most common hinge types can be made from stainless steel: piano hinges or continuous hinges, butt hinges, strap hinges, weld on hinges, spring hinges and friction hinges. Piano stainless steel hinges are able to provide consistency in strength along the entire length of the hinge, thus supporting the objects to which they are attached and reducing the gap between the objects and the hinges. Butt stainless steel hinges are a type of hinge with rectangular parts that fasten to two separate, parallel parts that close on each other, thus connecting them and allowing for swinging movement up to 180 degrees.

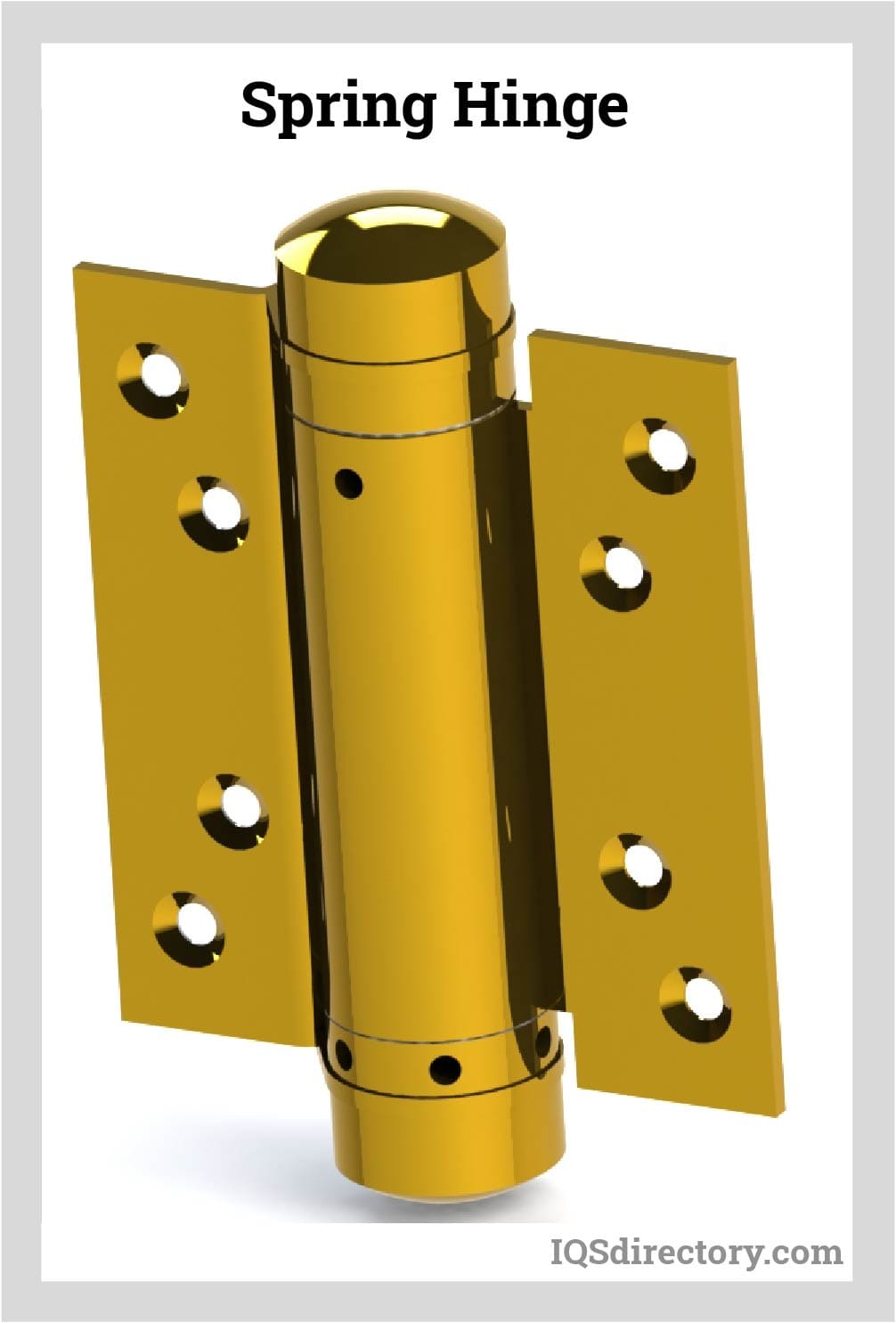

Strap stainless steel hinges are a type of hinge with long straps that attach to the surface face of exterior and interior doors as well as cabinets. Weld on stainless hinges are small hinges that are designed as two halves of a hinge that can separately be directly welded onto the surfaces and are able to withstand substantial loads. Spring stainless steel hinges are spring loaded hinges used for applications that require keeping a door or gate in a closed or open position for an extended period of time.

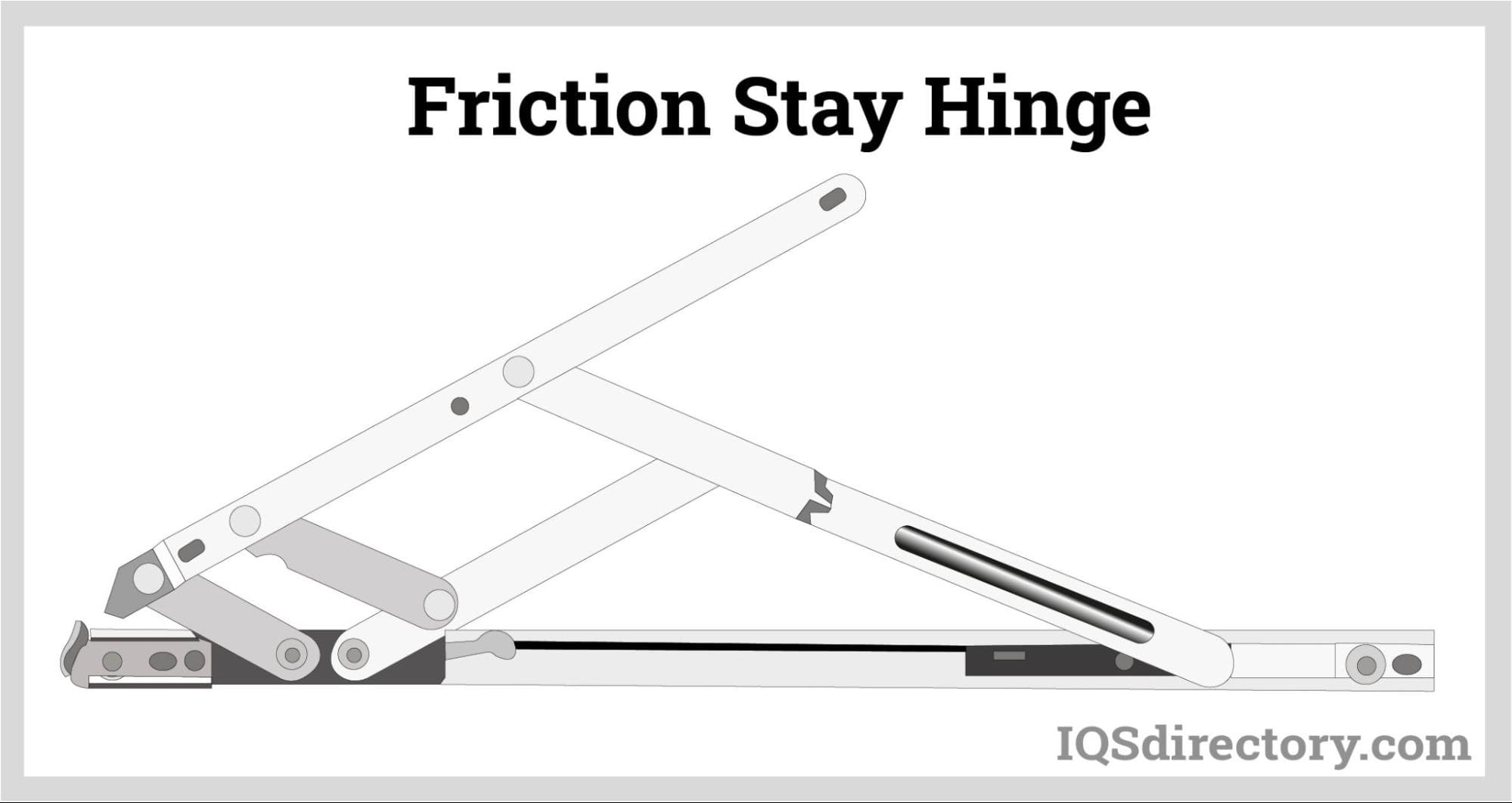

Friction stainless steel hinges provide precise positioning capabilities while allowing for smooth controlled flow from one position to another. Most types of hinges are made by first extruding the stainless steel material and then cutting and drilling it to shape. Stainless steel hinges may also be stamped or roll formed, but the extrusion process is the most common because it adds extra tensile strength to the hinge.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services