When describing an industrial hinge, the first words that come to mind are “heavy duty”. This is the main and required characteristic of these sturdy and dependable mechanisms that hold metal doors in place and ensure reliable and guaranteed use without fatigue or wear. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Slip hinges, continuous hinges, butt hinges, flag hinges and any custom hinge need – Delson Hinge has over 50 years of experience to bring you a better hinge making process. Not only the highest quality standard and custom hinges, but also exceptional service, prices and turnaround. With custom hinge design being our forte, Delson can truly say that we offer a hinge for every need!

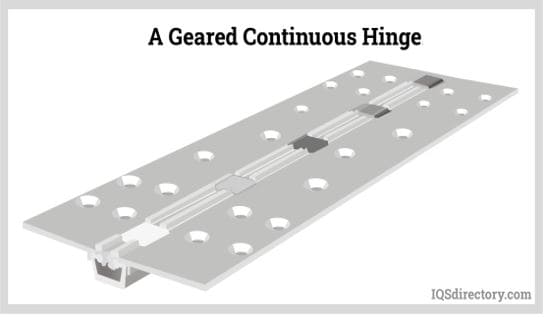

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Industrial Hinge Manufacturers

Typical hinges for industrial use are made of a sturdy metal such as steel or stainless steel. The grades of these metals, that are chosen for the production of hinges for manufacturing and production complexes, are malleable, formable, and sturdy with high tensile strength. They have to be able to endure the constant stress and strain of an active work environment.

Only certain types of steel can be used to produce industrial hinges. It has to be flexible enough to be customized but sturdy and durable enough to withstand constant stress and wear. A typical grade of American Society for Testing and Materials (ASTM) grade of steel chosen for the process is ASTM grade 1018, which is a medium low-carbon steel. It can be shaped to a variety of lengths and widths as well as be welded for custom applications.

Stainless steel has become one of the most popular metals for the production of a variety of products, including hinges. Two of the grades most commonly used for industrial hinges are SAE 304L and SAE 316L, which are strong, malleable, and corrosion resistant. Other grades, such as ASTM grade 1018, SAE 304L and SAE 316L are formable and can be shaped into hinges for unusual conditions.

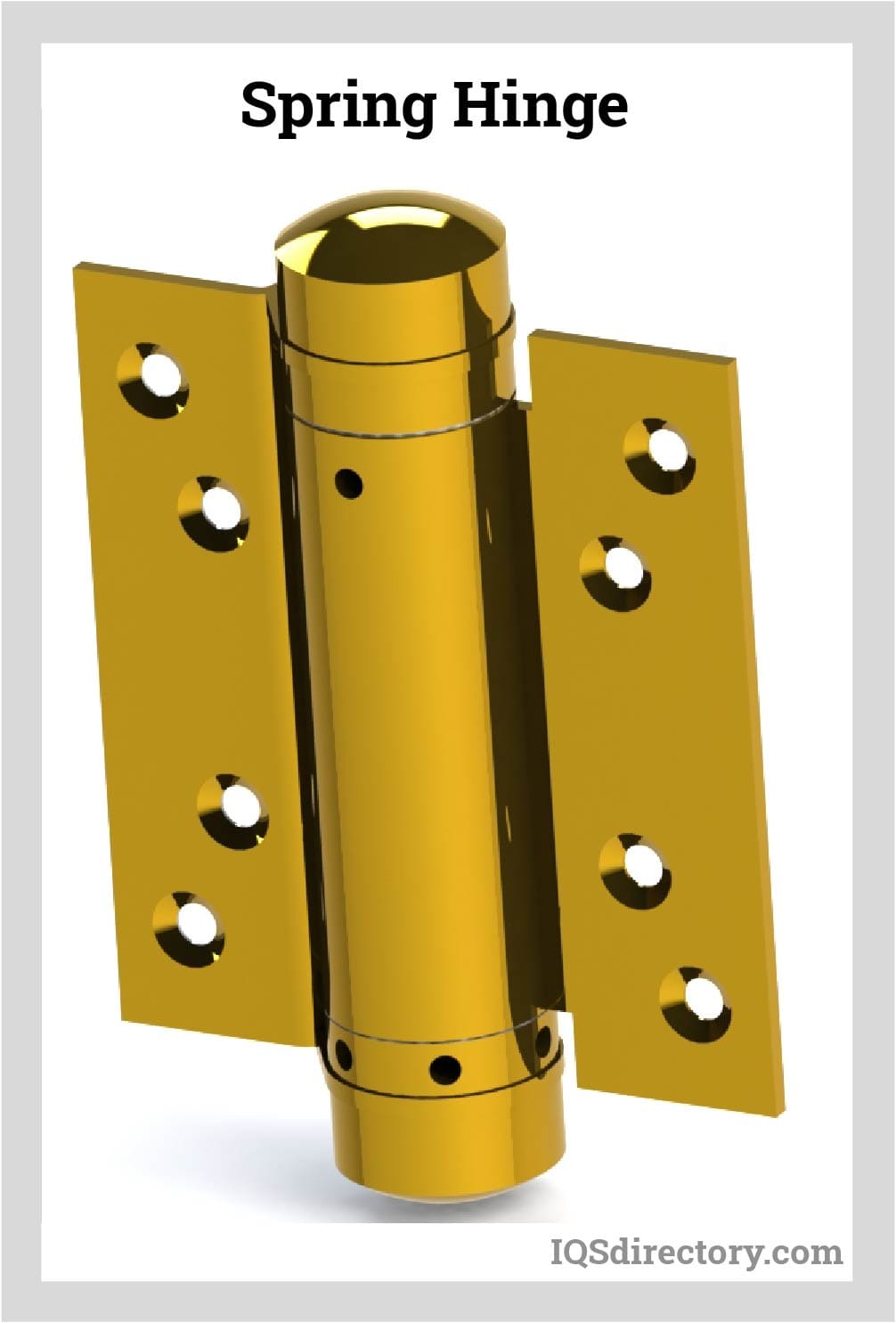

There are a wide variety of conditions and situations that require heavy duty hinges such as gates to secure locations, storage cabinets, radiation doors, and various types of automated equipment. The requirements and expectations for industrial hinges is like any other piece of manufacturing machinery. They must be long lasting, durable, and reliable. Though they may not be a major investment, due to the processes required to produce them, they are substantially more expensive than a hinge on a bedroom door or closet.

Unlike common hardware store hinges, ones made for industrial use are usually delivered raw so that they can be shaped and formed to fit the customer’s application due to the fact that products such as industrial doors, are not standard and are designed for specific applications. The steel and stainless steel for industrial hinges is pliable enough to be drilled, bent, cut, and deformed so that a hinge can be fitted to its use.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services