Heavy-duty hinges stabilize large, frequently used doors, gates, or furniture lids. Typically, they are composed of stainless steel or thicker steel. Additionally, they are built to operate more smoothly with heavier doors than their regular equivalents. These hinges come in sizes ranging from 6″ to over 24″. The sole thing that sets heavy-duty hinges from regular hinges is their capacity to support significant weight. They are otherwise identical to other hinges in appearance and operation. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Slip hinges, continuous hinges, butt hinges, flag hinges and any custom hinge need – Delson Hinge has over 50 years of experience to bring you a better hinge making process. Not only the highest quality standard and custom hinges, but also exceptional service, prices and turnaround. With custom hinge design being our forte, Delson can truly say that we offer a hinge for every need!

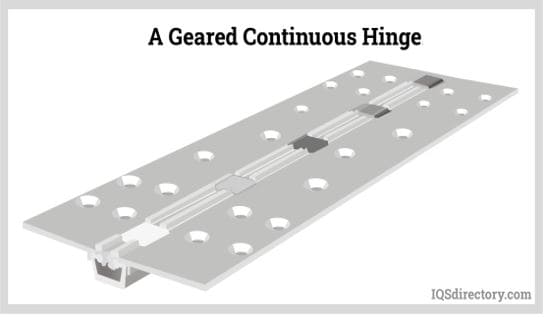

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Heavy Duty Hinge Manufacturers

Design of Heavy-Duty Hinges

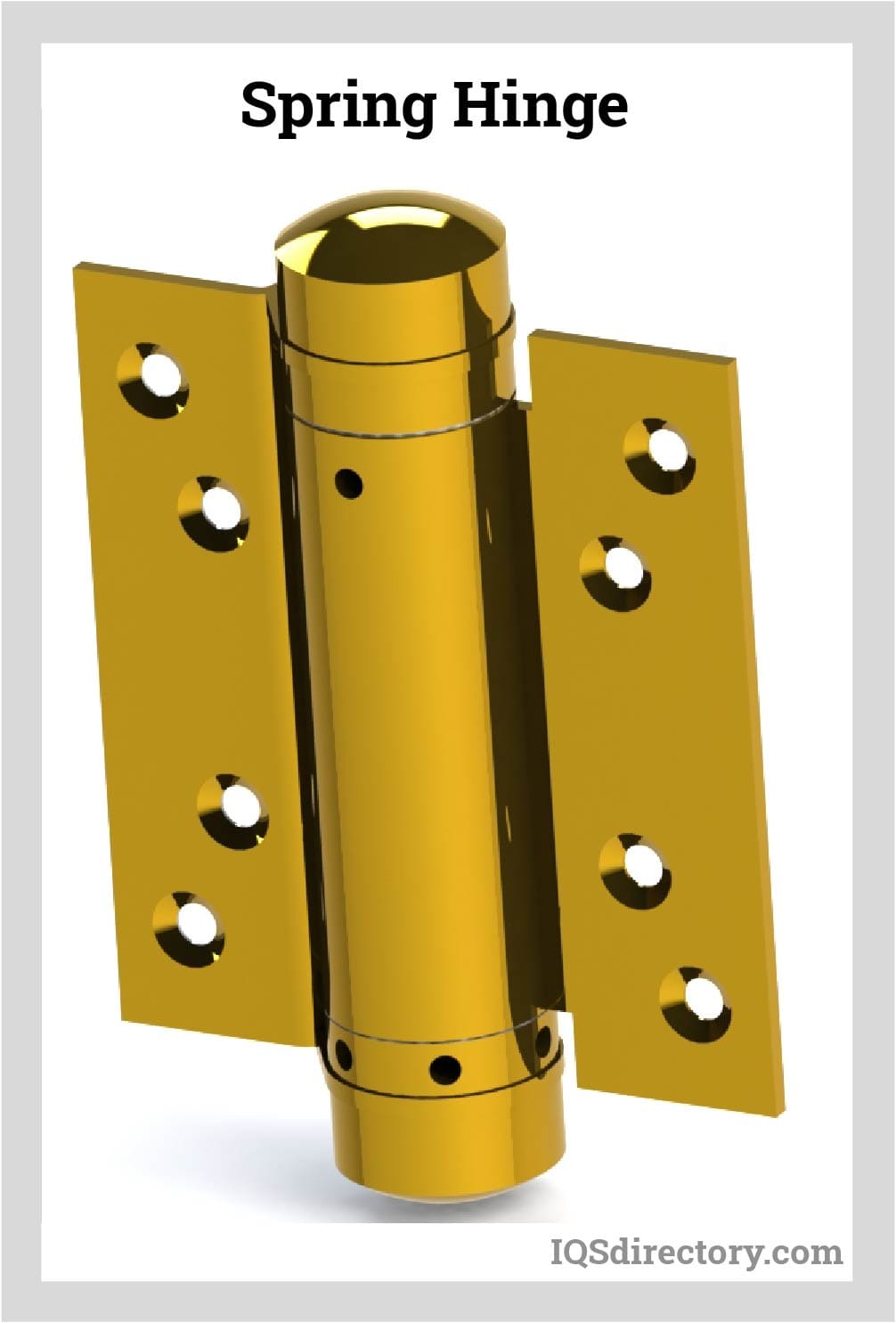

Heavy-duty hinges often have material thicknesses up to one-quarter inch. They can also be produced to almost any length requirement. Aluminum, brass, bronze, copper, galvanized steel, stainless steel, steel, and titanium are a few of the elements that are frequently utilized to create heavy-duty hinges. Because each material has a unique advantage, a customer's choice of hinge material is influenced by the application for which the hinge will be utilized. For instance, yellow-gold colored brass is a particularly appealing alloy.

It is frequently used to make heavy-strength, low-friction decorative hinges, especially with large door applications, because it is both moderately robust and extremely workable. The copper alloy bronze and the copper alloy brass are relatively similar, but bronze has a high concentration of tin, and brass has a high concentration of zinc. Bronze is ten percent less dense than stainless steel and is ductile, corrosion- and fatigue-resistant.

Additionally, bronze has a high level of resistance to saltwater corrosion. Therefore, heavy-duty bronze hinges are widely used in maritime applications and as door hinges on doors that are close to the ocean or a saltwater body of water. In addition, they are frequently used to support large doors and general cabinetry. Generally, a heavy-duty hinge will typically be built of stainless steel because steel alloys are robust.

Types of Heavy-Duty Hinges

Heavy-Duty Door Hinges

These door hinge types possess extreme load-bearing capacities. These hinges typically have two leaves and a knuckle in the middle. The maximum radial load-bearing capability ranges from 4000 lbs. to 25,000 lbs. The leaf thickness ranges from 3/8 to 3′′. These hinges are employed in R&D labs, nuclear-shielding doors, and the military and defense sectors.

Heavy-Duty Gate Hinges

These hinges have self-latching, anti-sag features that can also be padlocked for additional security. These gate hinges can hold gates that weigh between 1,000 and 40,000 lbs. Heavy-duty gate hinges are typically made of carbon steel or stainless steel, which are strong, corrosive-resistant, and anti-resistant. A heavy-duty gate's leaf thickness ranges from 1 to 3 inches, and its maximum radial load ranges from 400 to 25,000 pounds. These hinges are utilized in the construction, chemical, and refining industries.

Heavy-Duty Pivot Hinges

Typically, these hinges join any heavy door's top and bottom portions. Doors may be opened and closed in opposite directions thanks to these hinges. The materials utilized to make pivot hinges include carbon steel or stainless steel. These heavy-duty pivot hinges are made to hold up doors that weigh between 1,000 pounds and 40,000 pounds. The marine, petroleum, food processing, agricultural, and many more industries all use heavy-duty pivot hinges.

Strap Hinges

Strap hinges are a different kind of hinge that performs as well as heavy-duty hinges. Strap hinges are often constructed from a heavy-gauge metal, typically stainless steel, and mounted to the front of a large door.

Heavy-Duty Weld-on Hinges

Due to their superior load-bearing ability, heavy-duty weld-on hinges are employed in applications such as machine doors, steel gates, electrical boxes, etc.

Applications of Heavy-Duty Hinges

Heavy-duty hinges can serve various purposes because of the broad parameters that characterize them. They are often used as door suspension tools and exhibit exceptional performance, strength, and longevity. In addition, heavy-duty hinges are the strongest among a collection of hinges used for the same application when utilized in different situations. For instance, a stainless steel hinge supporting the operation of a metal industrial cabinet can be compared to a hinge supporting hardwood kitchen cabinets in a home to determine whether it is heavy-duty.

More uses of heavy-duty hinges are listed below.

Agricultural Applications: Truck bodies, tractors, and barn doors can all use heavy-duty hinges. These hinges support door weights ranging from several hundred pounds to as much as 20,000 pounds in some circumstances. Rather than being fixed to doors, these heavy-duty hinges, typically constructed of steel and weighing up to 55 pounds, are frequently welded to them. These kinds of hinges are useful in situations where the protection of animals and equipment is critical.

Building Applications: Hinges can be utilized for large window panels, FEMA doors, and hospital/medical facility construction and maintenance repairs.

Maritime Applications: They can be utilized in shipbuilding applications that call for compartment doors and explosion doors.

Military and Defense Applications: Heavy steel doors and panels on armored vehicles and closures are held in place by heavy-duty hinges.

Choosing the Right Heavy-Duty Hinge Supplier

To ensure you have the most positive outcome when purchasing heavy-duty hinges from a heavy-duty hinge supplier, it is important to compare several companies using our directory of heavy-duty hinge suppliers. Each heavy-duty hinge supplier has a business profile page highlighting their area of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each heavy-duty hinge business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services