A friction hinge operates by establishing a predetermined tolerance between the mechanical parts. A special kind of hinge known as a frictional hinge features smooth motion and angle retention. It operates on the idea of torque, which may be produced by exerting a specific force. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Slip hinges, continuous hinges, butt hinges, flag hinges and any custom hinge need – Delson Hinge has over 50 years of experience to bring you a better hinge making process. Not only the highest quality standard and custom hinges, but also exceptional service, prices and turnaround. With custom hinge design being our forte, Delson can truly say that we offer a hinge for every need!

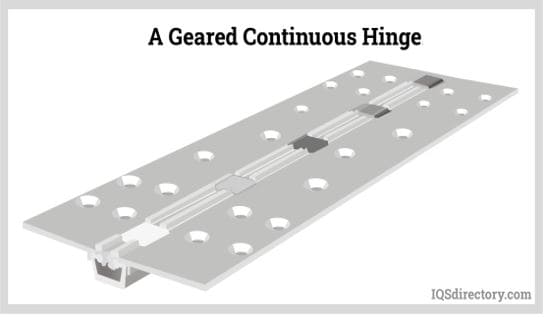

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Friction Hinge Manufacturers

Friction Hinges: Principles, Types, Materials, and Applications

If you’re researching friction hinges—sometimes known as torque hinges or resistance hinges—you’re likely interested in advanced hinge solutions that provide precise control, stability, and flexibility for doors, windows, electronic enclosures, automotive applications, and more. This comprehensive guide delivers everything you need to know about friction hinges, including their working principles, varieties, material choices, benefits, use cases, and how to choose a reliable supplier. Whether you are an OEM, architect, engineer, product designer, facility manager, or procurement professional, understanding friction hinges will help you make informed decisions for your next project.

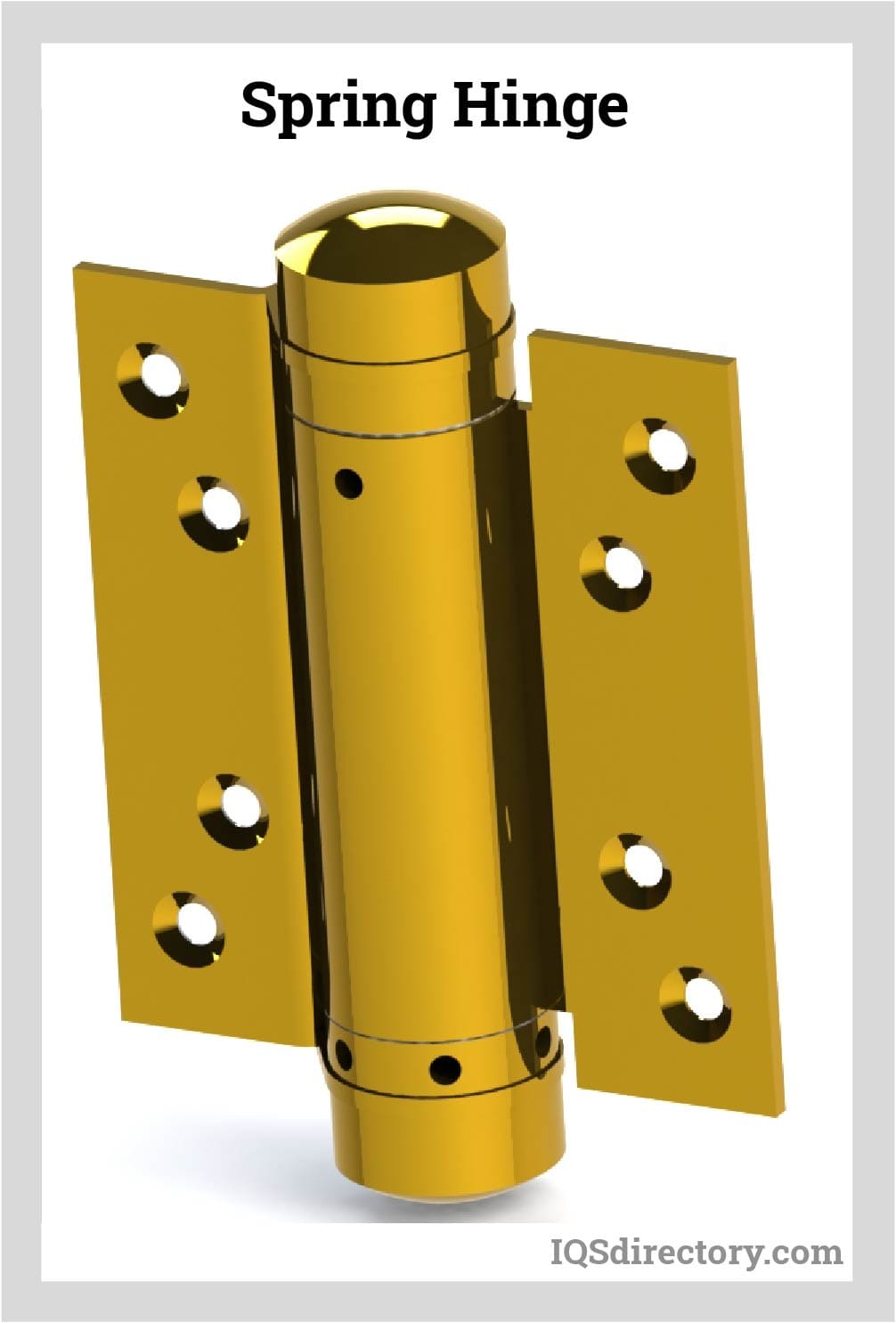

What is Torque in a Friction Hinge?

Torque is a unit of measurement for the rotational force required to spin or pivot an object around an axis. In friction hinges, torque determines how much force is needed to move the hinge and keep an object, such as a window sash or laptop screen, in a desired position. This force is managed and controlled through specialized engineering—most commonly via added friction, springs, or lubricants integrated into the hinge mechanism. By fine-tuning these elements, friction hinges provide smooth, dampened movement and controlled resistance, preventing unwanted slamming or drifting.

How Do Friction Hinges Work?

Doors, windows, electronic panels, and display devices often rely on friction hinges on both sides to manage the balance between mobility and stability. When these objects are opened or closed, force is exerted; friction hinges are designed to allow partial opening or closing and then reliably hold the object in a specific position for as long as needed. This ability is particularly valuable for applications where repeated repositioning or variable angles are necessary.

Friction hinges can be customized for one-way resistance (resistance on a single side) or two-way damping (resistance on both sides), allowing them to be tailored to an individual’s or application’s exact requirements. Factors such as viscosity, temperature tolerance, and resistance capability can all be specified for the intended use. This makes friction hinges a preferred solution in industries where performance and user experience are paramount.

Key Features and Selection Criteria for Friction Hinges

Choosing the right friction hinge for your application involves careful evaluation of several technical and operational features. Let’s examine the most important considerations:

-

Torque Requirement

Each application demands a specific torque for optimal hinge performance. Too little torque results in insufficient holding power, while too much torque can make operation difficult. Determining the required torque range is critical for ensuring the hinge meets both user expectations and safety standards.

-

Box Size

The hinge’s physical dimensions directly impact the overall package size and design flexibility. Compact friction hinges are especially valuable in electronics, aerospace, and medical devices where space is limited yet performance cannot be compromised.

-

Life Requirement (Durability)

The expected number of opening and closing cycles determines the hinge’s operational lifespan. Choose hinges rated for your application’s frequency of use, especially in high-traffic environments or mission-critical equipment.

-

Dynamic Torque

Dynamic torque refers to the hinge’s resistance during active rotation. This characteristic is key for applications requiring smooth, consistent motion without sudden stops or drops.

-

Static Torque

Static torque is the resistance needed to initiate hinge movement from a resting position. Monitoring and optimizing static torque ensures ease of use while maintaining secure positioning when the hinge is not in motion.

Additional features that may influence your hinge selection include:

- Spring back feature: Automatic return to a default position when released.

- Free play: Amount of movement within the hinge before resistance is felt.

- Aesthetic appeal: Surface finish, color, and design options for visible installations.

- Environmental resistance: Suitability for harsh conditions (humidity, salt spray, extreme temperatures).

- Custom designs: Tailored torque, form factor, or mounting solutions for unique projects.

Types of Friction Hinges: Options and Applications

Friction hinges come in various types, each engineered for specific installation styles and performance needs. Understanding these categories will help you select the best hinge for your application:

-

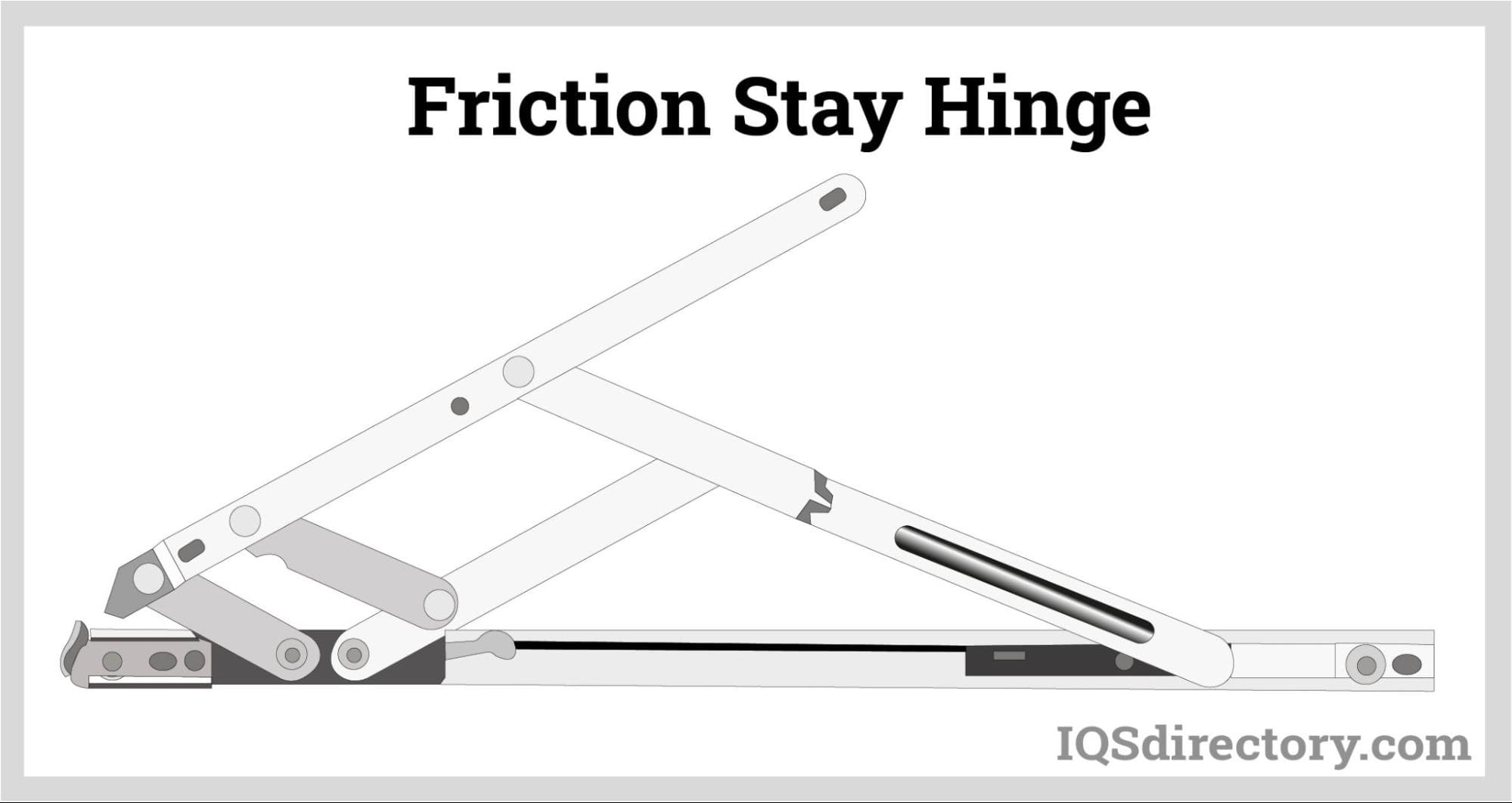

Friction Stay Hinge

Friction stay hinges are commonly used in window systems, offering variable friction to securely hold windows open at multiple angles. They are available in several subtypes:

- Standard friction stay hinge: Provides basic friction for standard windows.

- Restricted friction stay hinge: Limits window opening for enhanced safety and security.

- Easy clean friction stay hinge: Allows the window sash to pivot further for easier cleaning access.

-

Side Hung Friction Hinge

Side hung friction hinges are designed for windows that open like doors, with the hinge mounted on the vertical side. These are ideal for casement windows or doors requiring secure, adjustable positioning.

-

Top Hung Friction Hinge

Top hung friction hinges support windows with handles located at the bottom, allowing the sash to pivot outward from the top. They are popular in awning-style windows and certain commercial applications.

What Materials Are Used to Manufacture Friction Hinges?

Material selection is crucial for friction hinge performance, longevity, and appearance. Depending on the application, hinges may be constructed from:

- Fabrication skills: Precision manufacturing for reliable and consistent friction control.

- Physical characteristics: Strength, weight, and wear-resistance considerations.

- Corrosion protection: Critical for outdoor, marine, or industrial environments.

- Mechanical toughness: Ability to withstand repeated stress and heavy loads.

- External components: Compatibility with covers, bezels, or integrated electronics.

Common hinge materials include:

- Stainless steel: Excellent corrosion resistance; ideal for harsh environments and commercial buildings.

- Aluminum: Lightweight and rust-resistant; suitable for aerospace, automotive, and portable devices.

- Stainless 316 steel: Superior corrosion resistance for marine and chemical applications.

- Steel (cold-rolled/hot-rolled/galvanized): High strength and economic value for industrial or heavy-duty use.

- Brass alloy: Attractive appearance and moderate corrosion resistance for decorative hinges.

- 18-8 stainless steel: Common grade for general-purpose hinges.

- Titanium: Extreme durability, lightweight, and corrosion resistance for aerospace or medical applications.

- Copper: Sometimes used for aesthetics or electrical conductivity.

Explore the best material for your project by comparing the physical and environmental requirements—need help choosing? What type of hinge material is right for your application?

How Does a Friction Hinge Operate?

- Friction hinges are engineered with precise tolerances between mechanical components, ensuring consistent and reliable resistance throughout their range of motion.

- Additional materials—such as springs and lubricants—are sometimes incorporated to achieve the desired resistance level or to dampen hinge movement, providing either smoother action or a stronger hold.

- Depending on the design goal, friction hinges can be configured to permit rapid closure or to hold an object at any chosen angle, offering flexibility for both fully open and partially open states.

- For applications requiring secure positioning, torque can be specified to ensure the pivoting component remains stationary even when subjected to external forces (like wind or vibration).

Where Are Friction Hinges Used? Common Applications

Friction hinges provide value across a wide range of industries by adding controlled movement and stability to movable parts. Typical applications include:

- Doors and windows: Friction hinges offer flexibility and strength, allowing sashes and panels to be held at various angles without additional stays.

- Loading docks and high-traffic doorways: Hinges with frictional resistance can withstand lateral forces, increasing safety in busy environments.

- Consumer electronics: Used in adjustable laptop displays, tablets, monitors, portable DVD players, and medical equipment lids—enabling smooth, variable positioning without drift.

- Automotive sun visors and compartments: Friction hinges provide adjustable movement and help maintain the desired orientation under vibration or movement.

- Industrial enclosures and access panels: Securely hold covers open for maintenance, improving safety and convenience on the factory floor.

- Architectural and furniture hardware: Enables soft-closing cabinet doors or adjustable arms on desks and lighting fixtures.

Have a unique application in mind? Contact a friction hinge expert to discuss custom engineering solutions for your specific project.

Benefits of Friction Hinges

Why choose friction hinges over traditional continuous or butt hinges? Here are the key advantages:

- Enhanced sealing: The exterior rubber strip remains unbroken, improving the window or door’s weather seal and energy efficiency.

- Controlled opening angle: The hinge’s design allows for precise adjustment of the maximum opening angle, with options for installing a second arm for even greater control.

- Improved safety and ease of cleaning: Some friction hinges enable the window to pivot inward, making it easy to clean from inside the building and reducing the risk of falls or accidents.

- Superior wind resistance: Friction hinges resist wind pressure inherently, eliminating the need for additional wind bracing in many cases.

- Cost-effective solution: Friction hinges often deliver the same or better performance than alternative hardware, all at a competitive price point.

- Noise reduction: The dampened movement provided by friction hinges can minimize slamming and associated noise.

- Customizable performance: Manufacturers can tailor resistance, size, and finish to meet the requirements of demanding projects.

Still comparing hinge solutions? How do friction hinges compare to concealed, continuous, or piano hinges in your specific use case? Explore our guides on continuous hinges and butt hinges to learn more.

How to Choose the Best Friction Hinge Supplier

Selecting a reputable friction hinge manufacturer or supplier is vital for ensuring product quality, performance, and after-sale support. Here are the best practices for buyers and specifiers:

- Compare multiple suppliers: Use our directory of friction hinge suppliers to review business profile pages, learn about their experience and capabilities, and assess their product offerings.

- Request detailed information: Communicate directly with suppliers via the included contact forms to obtain technical data, lead times, pricing, and customization options.

- Evaluate website and certifications: Use our proprietary website previewer to quickly understand each supplier’s specialties and verify quality management certifications (such as ISO 9001 or industry-specific standards).

- Submit RFQs for competitive quotes: Our simple RFQ form makes it easy to request proposals from multiple companies at once, saving you time and ensuring you receive the best value.

- Ask about support and warranty: Reliable suppliers stand behind their products with strong technical support, installation guidance, and warranty coverage.

Ready to get started? Request a quote from leading friction hinge suppliers or contact our experts for personalized assistance in choosing the right hinge for your next project.

Frequently Asked Questions about Friction Hinges

- What is the difference between a friction hinge and a standard hinge?

A friction hinge provides controlled resistance to movement, holding a door, window, or panel at a set angle, while a standard hinge allows free movement without resistance. - Which industries commonly use friction hinges?

Friction hinges are widely used in architectural hardware, automotive interiors, consumer electronics, medical devices, industrial machinery, and aerospace engineering. - Can friction hinges be adjusted or repaired?

Many friction hinges feature adjustable torque settings, and some can be serviced or re-lubricated for extended life. Always check manufacturer specifications. - Are there corrosion-resistant friction hinges?

Yes, hinges made from stainless steel, aluminum, or with specialized coatings provide exceptional corrosion resistance for outdoor or marine use. - How do I know what size or torque rating I need?

Consult with your supplier or use online torque calculators, considering the weight, dimensions, and desired movement of your application. - What lead times can I expect for custom friction hinges?

Standard products may ship quickly, while custom-engineered hinges typically require longer lead times—plan accordingly and discuss timelines with your supplier. - Where can I buy friction hinges online?

Use our supplier directory to connect with verified friction hinge manufacturers and distributors for fast, reliable sourcing.

Explore More Resources

- Browse our Hinge Manufacturers Directory for comprehensive listings of friction hinge suppliers and related hardware.

- Request a Custom Quote for your next project—our team is ready to assist with engineering support and product recommendations.

Conclusion: The Value of Selecting the Right Friction Hinge

In summary, friction hinges deliver a unique combination of controlled movement, durability, and design flexibility. Their ability to hold objects at any angle, resist environmental stresses, and adapt to custom requirements makes them indispensable in windows, doors, electronics, and industrial equipment. By understanding hinge types, materials, and application factors, and by partnering with a reliable supplier, you can ensure optimal performance, safety, and longevity for your installation.

For expert advice or to compare solutions, request a free consultation or quote today and discover how friction hinges can transform your next project.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services