From heavy-duty industrial equipment to residential doors, continuous hinges are designed to provide durability and longevity to products that require consistent and reliable operation. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

We are Northeast Hinge Distributors, a dedicated supplier of high-quality hinges engineered to meet the performance, durability, and aesthetic requirements of modern manufacturing and construction. We work closely with OEMs, fabricators, contractors, and maintenance teams to provide hinge solutions that integrate seamlessly into doors, enclosures, cabinets, access panels, and industrial equipment.

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Continuous Hinge Manufacturers

Components of Continuous Hinges

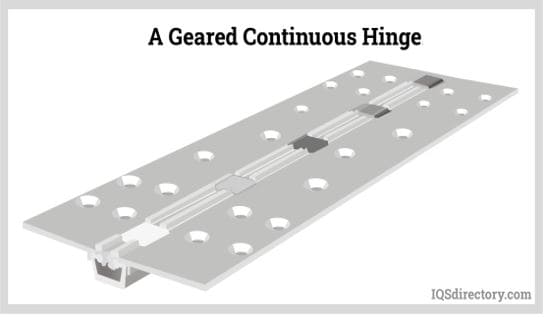

Continuous hinges consist of a series of interlocking leaves, knuckles, and pins that allow for smooth and continuous rotation around a fixed axis. The leaves are the flat, elongated pieces that attach to the surface and allow for the hinge to be mounted. Knuckles are cylindrical pieces that connect the leaves together and allow for the hinge to rotate. The pin is the central component that connects the knuckles together and allows for the hinge to rotate freely.

Types of Continuous Hinges

There are several types of continuous hinges, each designed for specific applications.

Piano Hinges

Piano hinges, also known as continuous hinges without holes, are the most common type of continuous hinge. They are named after their use in pianos but are used in many applications such as cabinetry, furniture, and musical instruments. Piano hinges consist of a long strip of metal with interlocking knuckles that allow for smooth and consistent operation.

Concealed Hinges

Concealed hinges, also known as invisible hinges, are designed to be hidden within the material they are mounted on. They are commonly used in cabinetry and furniture to provide a clean and aesthetically pleasing appearance. Concealed hinges consist of two interlocking leaves that are hidden within the material and allow for smooth and consistent operation.

Continuous Hinges with Holes

Continuous hinges with holes are designed for lightweight applications and can be easily mounted with screws or rivets. They are commonly used in electronic enclosures, access panels, and small doors. Continuous hinges with holes consist of a series of leaves with evenly spaced holes that allow for easy mounting and adjustment.

Weld-On Hinges

Weld-on hinges are designed for industrial applications and are permanently welded to the material they are mounted on. They are commonly used in heavy-duty equipment, gates, and fences. Weld-on hinges consist of a series of interlocking leaves with a central pin that is welded to the material for a secure and permanent mounting solution.

Strap Hinges

Strap hinges are commonly used on doors, gates, and cabinets. They are designed for strength and durability and are often used in heavy-duty applications. Strap hinges consist of a long, narrow strip of metal with interlocking knuckles that allow for smooth and consistent operation.

Heavy-Duty Continuous Hinges

Heavy-duty continuous hinges are designed for large and heavy doors and gates that require a strong and durable hinge. They are commonly used in industrial and commercial settings such as manufacturing plants, warehouses, and shipping docks. Heavy-duty continuous hinges consist of a series of thick and robust leaves with interlocking knuckles that allow for smooth and consistent operation.

Considerations Regarding Continuous Hinges

While continuous hinges have many benefits, they also have some limitations. Weight limitations are a significant concern, and heavy doors may require additional support. Continuous hinges also have a limited range of motion and adjustability compared to other types of hinges.

Benefits of Continuous Hinges

However, the benefits of continuous hinges far outweigh their limitations. The durability and longevity of continuous hinges make them a cost-effective solution for many applications. They provide consistent and smooth operation and can withstand the wear and tear of continuous use. Additionally, they provide a secure and stable mounting solution, reducing the risk of sagging or misalignment.

Applications of Continuous Hinges

Continuous hinges are used in various applications across many industries, including:

Aerospace and Defense Industry

Continuous hinges are widely used in the aerospace and defense industry for their reliability, durability, and strength. They are used in aircraft doors, cargo hatches, and other structural components that require consistent and reliable operation.

Commercial and Residential Doors

Continuous hinges are used in commercial and residential doors for their smooth and consistent operation. They are commonly used in high-traffic areas where frequent use can cause traditional hinges to wear out quickly. Continuous hinges also provide increased security and stability compared to traditional hinges.

Automotive Industry

Continuous hinges are used in the automotive industry for their strength and durability. They are used in doors, hoods, and trunks and are designed to withstand the wear and tear of frequent use. Continuous hinges also provide a secure and stable mounting solution, reducing the risk of misalignment or sagging.

Marine Industry

Continuous hinges are ideal for the marine industry as they are resistant to corrosion and can withstand exposure to saltwater and harsh weather conditions. They are used in boats and ships for hatches, doors, and cabinets.

Furniture Industry

Continuous hinges are commonly used in the furniture industry for their aesthetic appeal and smooth operation. They are used in cabinets, doors, and other furniture pieces where consistent operation is essential.

Industrial Equipment

Continuous hinges are used in industrial equipment such as conveyors, machinery guards, and access doors. They provide a reliable and consistent mounting solution that can withstand the harsh conditions of industrial environments.

Electronic Enclosures

Continuous hinges are used in electronic enclosures such as server racks, data cabinets, and control boxes. They provide a secure and stable mounting solution for these sensitive electronic components.

Choosing the Correct Continuous Hinge Manufacturer

To ensure you have the most beneficial outcome when purchasing continuous hinges from a continuous hinge manufacturer, it is important to compare several companies using our directory of continuous hinge manufacturers. Each continuous hinge manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each continuous hinge business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple continuous hinge companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services