Door hinges must, first and foremost, be fairly strong since continual usage exposes them to rust and wear. Even though stainless steel is just as robust as brass, it is very prone to rust, especially in areas close to saltwater or seas. This disqualifies it from use as an outside hinge. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Slip hinges, continuous hinges, butt hinges, flag hinges and any custom hinge need – Delson Hinge has over 50 years of experience to bring you a better hinge making process. Not only the highest quality standard and custom hinges, but also exceptional service, prices and turnaround. With custom hinge design being our forte, Delson can truly say that we offer a hinge for every need!

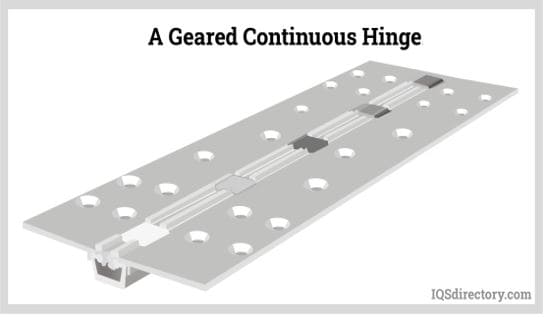

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Brass Hinge Manufacturers

Brass Hinges: Durability, Design, and Applications for Residential and Commercial Doors

When it comes to selecting the best door hinges for longevity, aesthetic appeal, and reliable functionality, brass hinges stand out as a top choice for both residential and commercial settings. Door hinges must, first and foremost, be exceptionally strong and resilient, as continual use exposes them to friction, environmental stress, and potential corrosion. The selection of hinge material plays a crucial role in the durability and performance of door hardware. While stainless steel hinges are robust and commonly used, they may be susceptible to rust—particularly in coastal environments or areas exposed to saltwater and humidity. This makes stainless steel less suitable for certain exterior applications.

In contrast, brass hinges offer a compelling combination of strength, corrosion resistance, and timeless appearance. Brass, being an alloy of copper and zinc, is highly robust and can withstand adverse weather conditions—including rain, smog, humidity, and salt air—making it ideal for exterior doors and challenging climates. With proper finishing and optional saltwater treatments, brass maintains its integrity and appearance over time. Brass hardware can also be manufactured in thicker profiles compared to stainless steel, allowing for enhanced stability and decorative flexibility.

Why Choose Brass Hinges Over Steel or Stainless Steel?

Are you wondering about the main differences between brass hinges and their steel or stainless steel counterparts? Here are some key considerations for buyers, architects, and contractors:

- Corrosion Resistance: Brass hinges inherently resist corrosion and rust, even in demanding environments where steel may fail. This makes them a preferred choice for exterior doors, gates, and windows.

- Visual Appeal: Brass provides a warm, golden finish and can be polished, lacquered, or plated to achieve a wide variety of colors and surface textures. This versatility makes brass hinges suitable for vintage, Victorian, antique, and contemporary designs.

- Durability: While brass hinges generally cost more than steel, they offer a longer lifespan, excellent structural integrity, and a premium finish that enhances the value of finished doors and cabinetry.

- Customization: Brass is highly workable and can be manufactured in intricate patterns and custom designs, ideal for restoration projects or statement hardware.

- Antibacterial Properties: With its high copper content, brass offers natural antimicrobial and antibacterial qualities, enhancing hygiene for high-touch areas.

Considering an upgrade to your door hardware? Need corrosion-resistant hinges for coastal construction? Explore hinge design options and contact reputable manufacturers for custom solutions.

Materials Used in Brass Hinges: Alloy Composition and Components

Modern brass hinges are precision-engineered from high-quality alloys, typically comprising copper and zinc in varying proportions to optimize mechanical strength and corrosion resistance. The unique properties of brass allow for the production of hinges that are both decorative and highly functional, making them a staple in premium architectural hardware.

- Brass Alloy: Most brass hinges are made from a carefully balanced mix of copper and zinc, with optional additions of lead or tin for enhanced machinability.

- Patina Potential: Brass naturally develops a patina over time, which can be either embraced for an antique look or prevented with lacquered finishes.

- Leaf Plate: The largest part of the hinge, the leaf plate, attaches the door to the frame and is typically drilled for secure screw mounting.

- Knuckle and Barrel: The central section of the hinge, composed of interlocking knuckles, forms the barrel that houses a removable or fixed pin.

- Hinge Pin: This component allows the door to pivot smoothly; it can be removed for door removal or replacement.

- Finishing Options: Brass hardware can be finished in polished, lacquered, chrome-plated, oil-rubbed, or antique patinas to match any design scheme.

- Protective Coatings: High-performance lacquer or plating is often applied to enhance durability and prevent tarnishing in high-traffic or exterior installations.

Looking for a specific finish or hinge style? Browse our hinge design resources for inspiration.

Construction and Manufacturing of Brass Hinges

The construction process for solid brass hinges involves advanced manufacturing techniques to ensure precision, strength, and smooth operation. Here’s a closer look at how premium brass hinges are made:

- Extrusion and Fabrication: Solid brass stock is extruded, cut, and machined to exact tolerances for consistent quality and fit.

- Precision Bearings: Heavy-duty brass hinges may include ball bearings or specialty bearing systems, supporting doors weighing up to 176 lbs (80 kg) or more.

- Fire Resistance: Many commercial brass hinges are independently tested and certified for fire-rated doors, meeting rigorous safety and performance standards (CE mark, UL listing).

- Antibacterial Performance: The high copper content in brass provides inherent antimicrobial protection, ideal for healthcare, hospitality, and public buildings.

- Versatile Sizing: Brass hinges are available in a wide range of sizes and thicknesses to accommodate everything from lightweight cabinets to heavy commercial doors.

- Customization: Manufacturers can create custom profiles, decorative finials, and personalized stamping for restoration projects or brand consistency.

How Do Brass Hinges Work? Essential Functions and Mechanisms

At their core, brass hinges connect two solid surfaces—most commonly, a door and its frame—allowing smooth and controlled movement. The basic working mechanism includes:

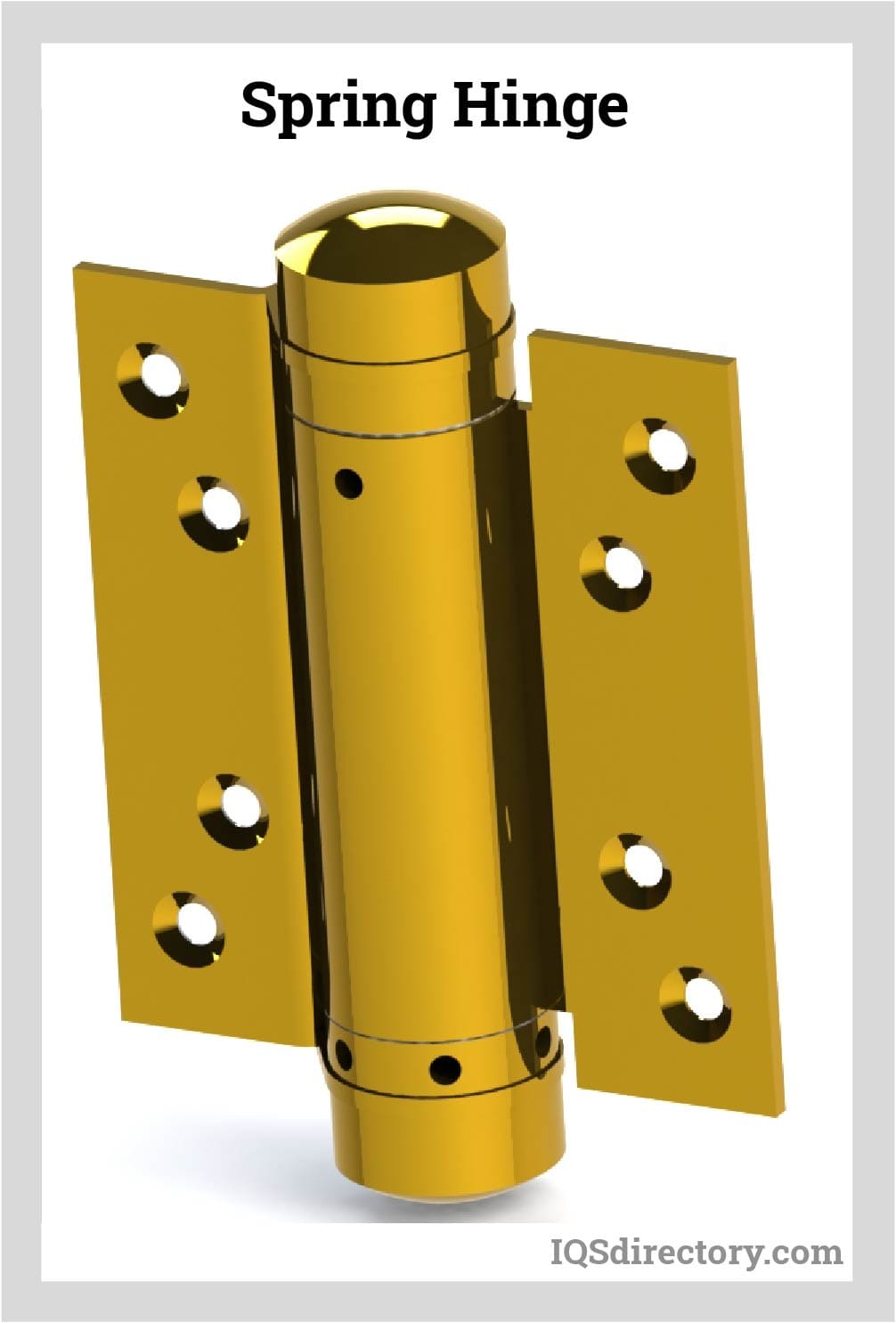

- Pivotal Motion: The barrel and pin assembly enables the door to open and close with minimal resistance.

- Load Bearing: High-quality brass hinges support the weight of the door, preventing sagging or misalignment over time.

- Reduced Friction: Brass’s natural lubricity, combined with precision engineering, ensures long-lasting, squeak-free operation.

- Compatibility: Brass hinges can be used with wood, metal, or composite doors, making them suitable for a wide variety of applications.

Curious about which hinge type is best for your project? Compare hinge styles and specifications to make an informed choice.

Key Benefits of Brass Hinges: Why Brass Remains a Top Choice

- Durability: Brass hinges can withstand years of use, adverse weather, and high-traffic environments while maintaining structural integrity.

- Malleability and Strength: Brass is both strong and ductile, allowing for the creation of robust, dependable hardware that resists breakage but can be readily formed into detailed shapes.

- Corrosion and Rust Resistance: Unlike steel, brass resists oxidation and does not rust, making it an excellent choice for humid or outdoor settings.

- Timeless Appearance: Brass offers a classic, upscale aesthetic that enhances doors, cabinets, and furniture with a warm, inviting glow.

- Variety of Finishes: From high-polish to brushed, antique to lacquered, brass is versatile enough to complement any interior or exterior design.

- Antimicrobial Properties: Brass’s copper content provides natural protection against bacteria, ideal for healthcare and hospitality environments.

- Low Maintenance: Quality finishes and coatings minimize the need for frequent cleaning or polishing.

- Value Addition: Brass hinges increase property value and appeal by combining beauty and performance.

Applications of Brass Hinges: Residential, Commercial, and Specialty Uses

- Residential Doors: Brass butt hinges and decorative hardware are widely used for interior and exterior doors, providing reliable performance and a sophisticated look.

- Cabinetry and Furniture: Brass cabinet hinges are popular for kitchen cabinets, wardrobes, dressers, and bespoke furniture, offering smooth operation and designer finishes.

- Windows and Shutters: Brass is ideal for window hinges and shutter hardware due to its resistance to weathering and attractive appearance.

- Antique Restoration: For historical and period-style buildings, brass hardware is essential for authentic restoration and preservation projects.

- Commercial Buildings: Offices, hotels, and public spaces often use brass hinges for entryways, conference rooms, and decorative doors, thanks to their durability and low maintenance.

- Marine and Coastal Construction: Brass’s corrosion resistance makes it a top choice for doors and hatches in marine, boating, and coastal environments.

- Specialty Hardware: Brass is frequently used in specialty hinges for pianos, jewelry boxes, and display cases where precision and aesthetics are paramount.

- Fire-Rated and Security Doors: Certified brass hinges are used in fire-resistant doors and high-security applications, meeting stringent safety regulations.

- Decorative Accents: Brass’s malleability allows for ornate patterns, engravings, and custom finishes, making it perfect for bespoke architectural hardware.

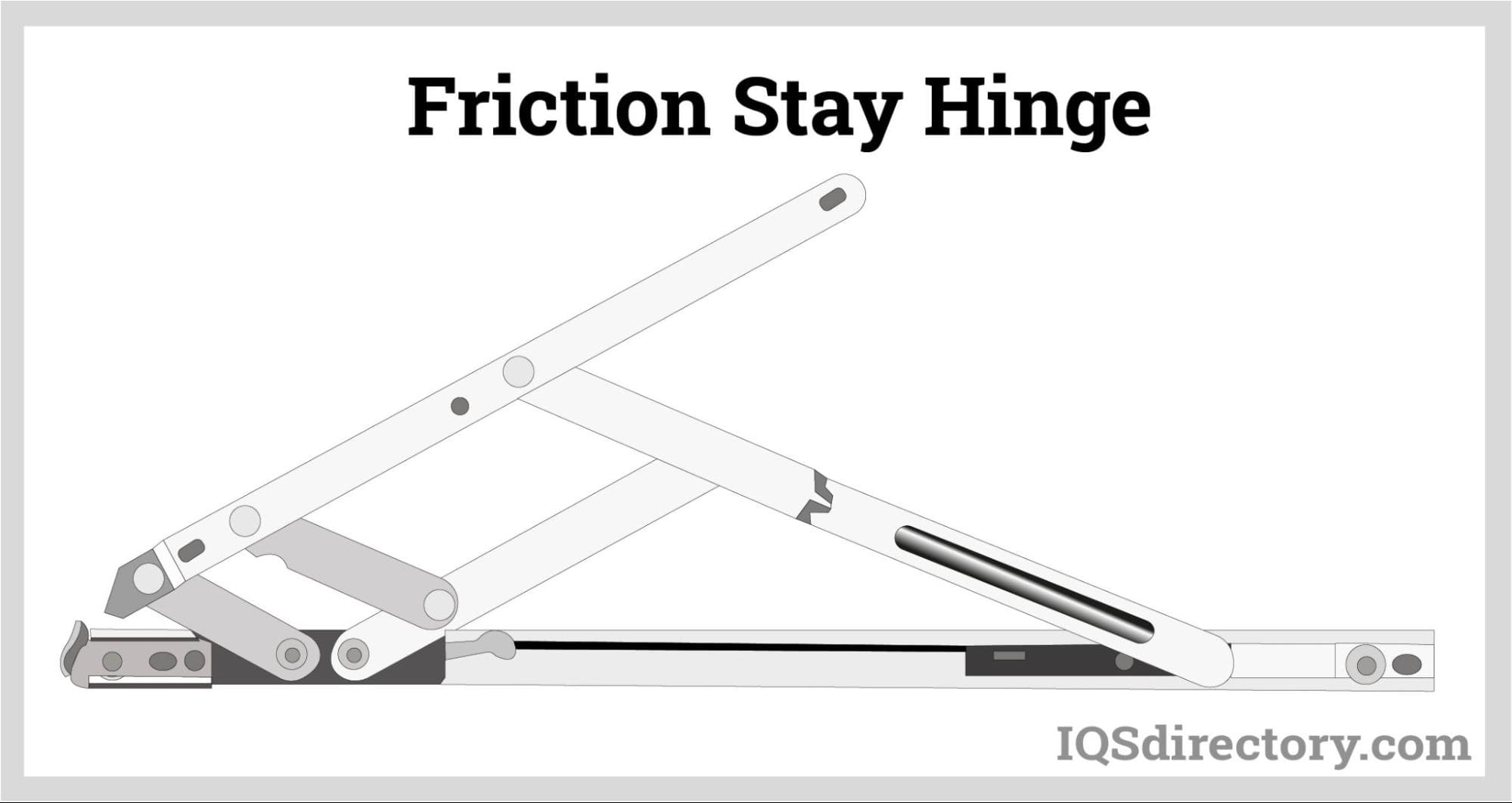

- Friction Hinges: Because brass produces less friction than many other metals, it is highly effective in applications where smooth, controlled movement is essential.

How to Select the Right Brass Hinges for Your Project

Are you searching for the best brass hinges for your home renovation, commercial build-out, or restoration project? Here are some key factors to consider before making your purchase:

- Load Capacity: Assess the weight and size of your doors or panels. Heavier doors require heavy-duty brass hinges with reinforced bearings.

- Environmental Conditions: For outdoor or humid environments, opt for brass hinges with weatherproof finishes or marine-grade alloys.

- Design and Finish: Match the hinge style and finish to your overall design scheme, whether you prefer polished, satin, antique, or custom-plated brass.

- Security and Compliance: For commercial or fire-rated doors, ensure the hinges meet required certifications and safety standards.

- Ease of Installation: Choose hinges with pre-drilled holes, removable pins, or adjustable features for straightforward installation and maintenance.

- Budget: While brass hinges can be more expensive than steel, their durability and visual appeal often justify the investment for high-value projects.

- Manufacturer Reputation: Select hinges from established manufacturers with proven quality control, warranties, and customer support.

- Customization Options: If your project calls for unique dimensions, shapes, or decorative elements, inquire about custom manufacturing capabilities.

Need expert assistance? Contact a hinge design specialist to discuss your requirements and receive tailored recommendations.

Brass Hinge Finishes and Aesthetic Options

Brass hinges are celebrated not only for their strength and performance but also for their decorative versatility. Here are some popular finish options to elevate your project’s design:

- Polished Brass: Offers a shiny, gold-colored finish for traditional and upscale interiors.

- Antique Brass: Features a darker, patinated look, ideal for period homes and vintage-inspired renovations.

- Brushed or Satin Brass: Presents a matte, understated appearance that complements modern and transitional spaces.

- Oil-Rubbed Brass: Adds depth and character, often used in rustic or industrial settings.

- Chrome-Plated Brass: Provides a sleek, contemporary feel with added corrosion resistance.

- Lacquered Brass: Sealed with a protective lacquer to prevent tarnishing and simplify maintenance.

- Custom Plating: Manufacturers can apply specialty finishes, such as nickel, bronze, or black, to match unique design requirements.

Looking for matching door hardware or cabinet pulls? Browse our cabinet hinge selection for coordinated solutions.

Frequently Asked Questions About Brass Hinges

- What are the main advantages of brass hinges over stainless steel or steel hinges? Brass hinges offer superior corrosion resistance, a wider variety of finishes, and natural antimicrobial properties, making them ideal for both decorative and functional applications.

- Do brass hinges tarnish over time? Unfinished brass will develop a natural patina, but lacquered or plated finishes can help maintain the original appearance for many years.

- Are brass hinges suitable for exterior doors? Yes, especially when properly finished or treated for weather resistance. They are commonly used in coastal and humid environments.

- Can brass hinges be used with heavy doors? Yes. Heavy-duty brass hinges with reinforced bearings are designed to support substantial weight without deformation.

- Are brass hinges more expensive than other types? Generally, yes; however, their durability and premium appearance often justify the higher initial investment.

- How do I care for brass hinges? Use a soft cloth for regular cleaning, and avoid abrasive cleaners. For polished brass, occasional buffing may be required to maintain shine.

Buyer’s Guide: How to Choose the Best Brass Hinge Manufacturer

To ensure the best results when purchasing brass hinges for your project, it’s crucial to partner with a reputable brass hinge manufacturer. Here’s how to make an informed decision:

- Research Manufacturer Credentials: Use our directory of brass hinge manufacturers to compare company profiles, capabilities, and areas of expertise.

- Evaluate Product Quality: Review product specifications, material certifications, and customer testimonials for assurance of quality and performance.

- Request Samples: Ask for sample hinges or finish swatches to verify fit, finish, and construction quality before placing large orders.

- Customization and Support: Choose manufacturers that offer custom design services, technical support, and responsive customer service.

- Use Our RFQ Form: Streamline your purchasing process by submitting a single Request for Quote to multiple suppliers using our simple online form.

- Preview Company Websites: Take advantage of our patented website previewer to quickly compare manufacturers and identify the best partner for your needs.

Ready to source high-quality brass hinges for your next project? Compare hinge manufacturers and request quotes today to secure the best solutions for your doors, cabinets, and architectural hardware needs.

Explore More About Brass Hinges and Door Hardware

Want to learn more about hinge types, finishes, or installation techniques? Browse our expert guides and resources:

- Hinge Design Guide

- Cabinet Hinges Buyers’ Guide

- Friction Hinges and Specialty Applications

- Hinge Manufacturers Directory

Still have questions? Contact us for personalized recommendations, technical details, and support with your hinge selection process.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services