Aluminum is the perfect solution for the fabricating of durable and long lasting hinges. Aside from its light weight, aluminum is corrosion and rust resistant making it applicable for a wide variety of applications from airplane hinges to door hinges on ocean going speedboats. Since aluminum is formable and workable, it can be shaped, fashioned, and designed to fit on a cupboard door or a hinged window. Read More…

We take our customer evaluations as our only measure of success. If our customers are not happy, we are not happy! We will work with you until we find the right hinges solution for you.

We are here to provide you with any hinge you could ever possibly need! We are the hinge specialists committed to bringing you a level of customer service that is unmatched by the competition.

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Slip hinges, continuous hinges, butt hinges, flag hinges and any custom hinge need – Delson Hinge has over 50 years of experience to bring you a better hinge making process. Not only the highest quality standard and custom hinges, but also exceptional service, prices and turnaround. With custom hinge design being our forte, Delson can truly say that we offer a hinge for every need!

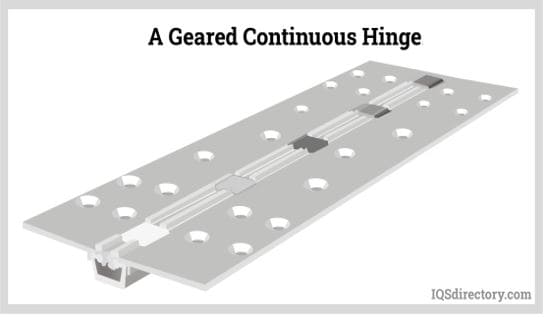

At SELECT Hinges, we have been manufacturing high-quality hinges since 1989. We produce continuous-geared aluminum hinges as well as continuous pin and barrel hinges for doors that are subject to constant traffic. Our hinges are designed to withstand frequent use and have been tested for over 25 million cycles. Models are available for new construction or use on existing doors.

More Aluminum Hinge Manufacturers

The lightweight of aluminum can be deceptive and lead people to believe that it doesn’t have much strength or tolerance. That is the beauty of it. Though it has a sleek appearance and lightweight, it has the same strength and endurance of some steels. It is one of the reasons that many builders choose aluminum hinges for their construction projects.

Since aluminum hinges have one third the weight of stainless steel, they are the number one hinge chosen for aircraft production, where being lightweight and reliable are essential. Regardless of the required length or hinged joint for an airplane, aluminum hinges can be produced to exactly meet the specifications and dimensions.

There are certain varieties of aluminum that are perfect for making hinges. One of the most common ones is 5052, which has high fatigue strength with exceptional resistance to marine conditions. Its enhanced endurance as well as its bright and shiny appearance lends sturdiness and functionality for boat and marine use.

While aluminum 5052 has excellent strength for marine applications, aluminum 3003 is one of the more common types of aluminum used in the construction of homes and, especially, kitchen cabinets. Its light weight and corrosion resistance makes it perfect for kitchen cabinet hinges since it can withstand and endure everyday use.

Specialty aluminum hinges are designed and produced for unusual conditions beyond boats and airplanes. Anodized aluminum is used in doors and windows where there is the potential of fire. Since aluminum naturally forms an oxidation layer when it is exposed to the atmosphere, anodization enhances that natural phenomenon making the layer thicker and stronger. The result is an increase in an aluminum hinge’s ability to resist corrosion and wear.

Hospitals prefer the use of aluminum for hinges since they provide superior protection around the edge of doors that are wider, heavier, and subject to violent impact from stretchers and gurneys. The characteristics of aluminum safeguards patients and ensures the welfare of workers.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services